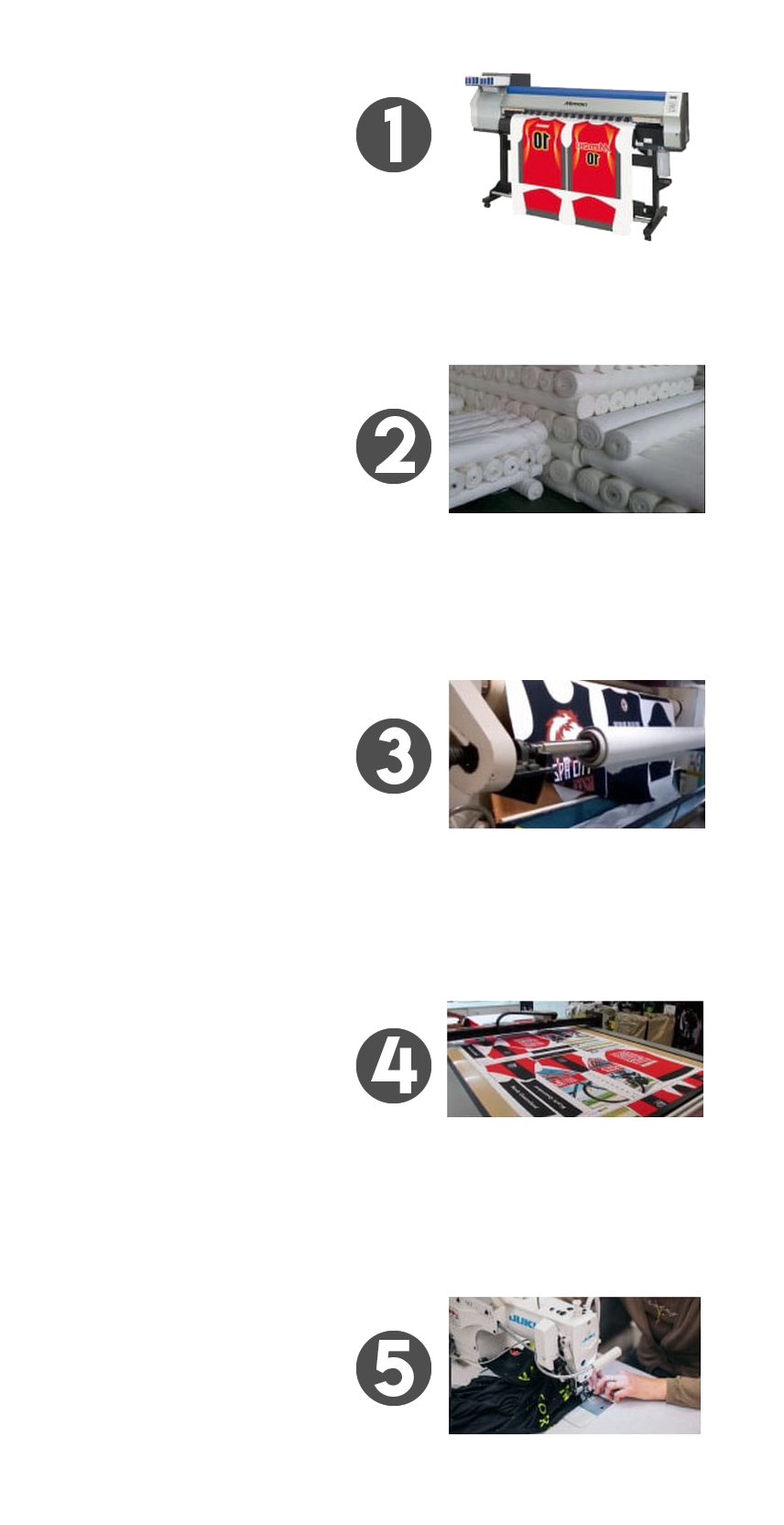

WE USE SUBLIMATION TECHNOLOGY

It all starts with a white fabric.

The white fabric is printed using wide-format sublimation machine. The fabric is then cut into shapes and into several panels using manual or digital laser cutters before the parts are sewn into one piece of apparel. The process requires meticulous graphics and color management, rigorous fabric selection, and precise machine-man coordination. Its main advantage over the other system is its being lightweight and having unlimited graphics. It is ideal for sportswear, compression garment, or even fashion apparel.

a. What is sublimation?

In layman’s term, sportswear sublimation is the process of printing a white fabric with the desired color or graphics. In making full-body sublimation sportswear, the fabric is usually in roll form (or unsewn) when printed, and later sewn into the desired apparel. Because there is almost no limit in color and graphics details that we can do with sublimation technology, we can also eliminate the need to cut and sew several colors of fabric for a specific color combination.

In technical terms, sublimation is the process of changing a solid to a gas without passing through the liquid phase. In sublimation printing, the solid here is the dried ink printed on a paper. When the ink is heated at a certain temperature, it changes into a gas. The gaseous ink transfers to the surface or substrate that it comes into contact with. The best substrate that absorbs the gaseous ink is something made of or coated with polymer.

Polyester is a category of polymer and it is the basic material used to manufacture sportswear fabric. Polyester is a thermoplastic material, which means that it becomes rubbery at its glass transition stage (Tg) when heated at around 160 degrees centigrade. At this stage, the polyester molecules open up to absorb the gaseous sublimation ink. The effective transfer of the sublimation ink into the polyester happens when the printed paper and the substrate are pressed together using a flat or roller heat press set at 190 to 200 degrees centigrade for about 1 minute.

When the heat press is released and the polyester is cooled, the gaseous sublimation ink turns into solid again and is embedded inside the molecules of the polyester. This process makes the print much more vibrant and longer lasting compared to other printing processes like screenprinting, film transfer, and DTG.

b. What is full sublimation?

Full sublimation is printing on the entire white fabric panel or roll using either a direct printing or transfer pressing. The color of the garment and the graphics are printed at the same time from edge to edge and sewn as garment with minimal seams. Because the seams are usually located at the sides, full sublimation is highly advisable for tight fits as the wearer will not feel any bulging or protruding seams inside the garment. Below is a singlet printed with full sublimation.

c. How many colors can we print?

Practically unlimited colors.

d. Why is sublimation considered the most durable, vibrant, and high-performing printing system for sportswear?

Sublimation does not fade and crack unlike silkscreen, vinyl transfer, and DTG printing. Sublimation printing is high-performing because it does not alter the moisture-wicking properties and breathability of sportswear. In addition, it is lightweight unlike silkscreened and appliqued jerseys.

Only sublimation can retain the moisture-wicking properties of dri-fit fabric